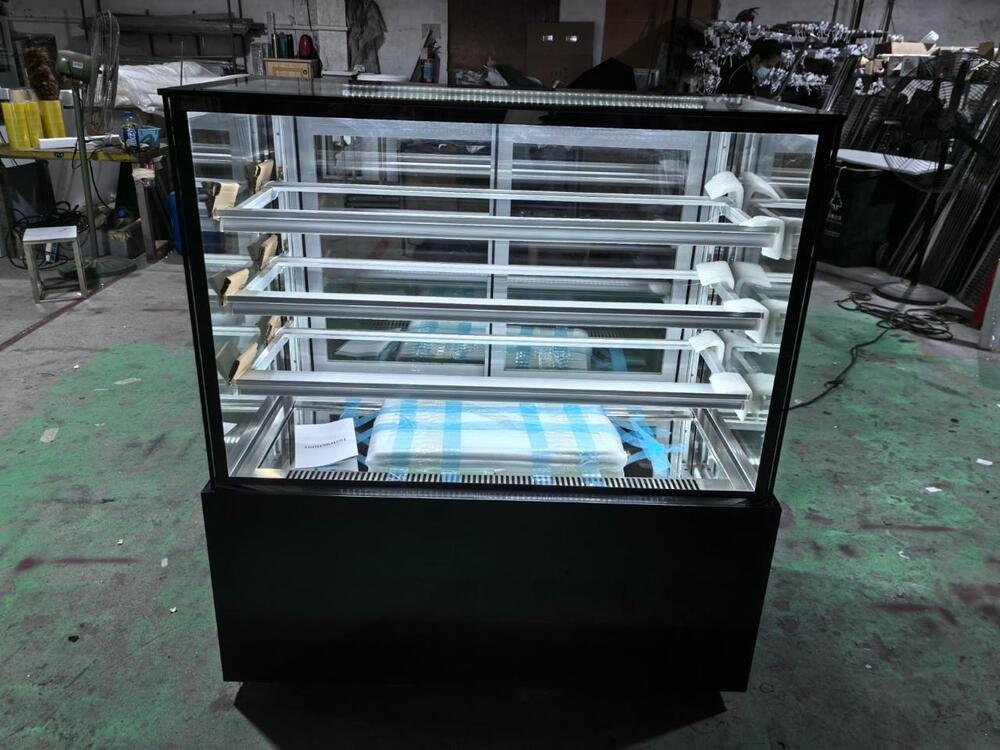

Showroom

"We are dealing only in Maharashtra, Gujarat, Goa & South India like Andhra Pradesh, Karnataka, Kerala, Puducherry, Tamil Nadu, Telangana, Chennai, Bangalore, Hyderabad, Coimbatore, Kochi, Trivandrum"

AL-BASIT IMPEX

GST : 27BGLPS3568R1Z7

GST : 27BGLPS3568R1Z7

Nanak Society, Rh:2, Sector 6, Plot No: 87, Next to Icici Bank, Kopar Khairane, Navi Mumbai - 400709, Maharashtra, India

Phone :08071630691

|

FALCON FOOD EQUIPMENT

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |